THE

CNC PROJECT

Part

3

DRAG

CHAINS

What

are drag chains?

They are a sort of hollow chain that is used to

carry the cables from the fixed part of a machine to the moving part

while protecting the cables and stopping them from getting tangled

up.

The

OneFinity I bought did not come with any and I wanted to add a

milling spindle with water cooling so I bought some and made my own

mountings to fit them to the 1F.

I first looked at what other people

had made on the 1F forums and one person was selling 3D printed drag

chain fittings - but when I looked at them I was not happy.

There

are three parts to such a set: the Top Mount, the X End Bracket and

the X Bend Mount that curves all of the cables 90 degrees and then

runs them into the second drag chain which goes to the benchtop.

This

is his Top Mount:

I

may not be a qualified engineer but I am pretty sure bending cables back 180

degrees is not a good idea.

Here

is his X End Bracket and X Bend Mount:

Not

bad but I think I can do a lot better. I also want to make sure that

my cooling pipes from the spindle are smoothly routed as any sharp

bend will restrict the flow.

I

started with cardboard and sticky tape: I stuck the bits onto the

machine with masking tape and marked where things went and fiddled

with things until it all worked right, then drew the shapes carefully

with compass and rulers.

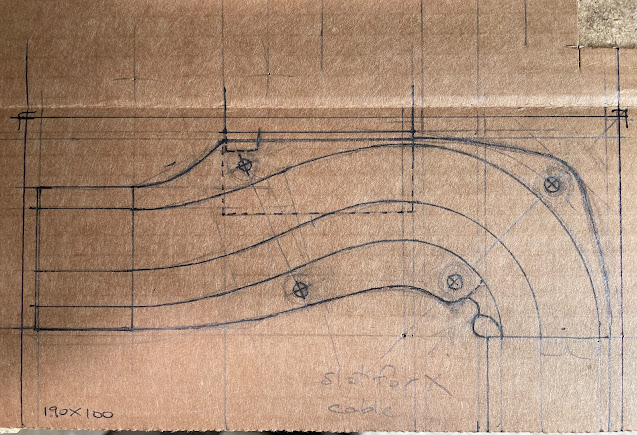

Here

is my pattern for the most important part, the X Bend Mount:

The

idea is that the fluid pipes will go round the outside of the curve

with the wires on the inside. The side walls are to be built up in

two layers of 5mm thick ABS sheet while the bottom is 2mm ABS sheet.

The

mountings use “L” shaped bits of the same 2mm sheet and three are

used – two for the Bend mount and one for the end mount that is

only there to support the aluminium rails that the drag chain rests

in.

Here

you can see the patterns and the parts ready to be cut from the

sheet:

On

the left are the side wall patterns and below them the bracket

pattern.

The

parts were first roughed out and then the sidewalls were glued

together to final thickness before lots and lots of cutting, filing

and sanding.

Note

that the glue faces must be sanded first and cleaned to get a good

gluing. I used “superglue” - I have some experience with it.

Note

also the use of masking tape to allow drawing on black plastic sheet,

an otherwise impossible task.

The

mounting brackets needed two bolt holes in them so I drilled these

and used the holes to bolt all three together for easier shaping.

During

the production some details of the design chainged but that is normal

and the main parts were checked repeatedly to make sure they would

fit as planned.

This

took some time but I think it all came together quite well.

Here

are the finished parts: On the left, the X End Bracket, right is the

X Bend Mount and below is the Top bracket.

My

brackets have a step for the drag chains to mount on so that the

cables run smoothly on and off the chains.

The

Top bracket has a magnetic fitting under it where a clip for the dust

boot pipe fixes on – you can see the magnet in the picture.

Here

is how they look fitted to the machine: you can see the rails that

the drag chain rests in on the X axis. Yes, I know it’s not all

polished but I don’t care: it’s not worth the trouble for a piece

of industrial machinery.

When

the pic was taken I was getting the rails for the Y chain ready to be

fitted. They are “L” profile alu extrusion screwed to the

benchtop.

You

can also see back end of the dust shoe I bought to run the suction

back and behind the drag chain rails. More about that in part 4.

Here

is another view of it, this time with the cooling pipes fitted and .

.

a

rope.

How

do you get the cables and pipes into the drag chains?

This

is my answer.

Get

a rope and a driver bit. I used a phillips bit as it was less likely

to catch on anything. It had a narrow collar near the back and I used

a small bit of thin iron wire to fix it to the end of the rope and

then covered it all with duct tape to make a smooth outside.

The

last part is a good strong magnet.

I

threaded the end into the drag chain and then use the magnet to pull

the driver bit along inside the chain from outside. When I got to

the bend I went right up to it, then moved the carriage so the bend

went past the driver bit then carried on pulling it with the magnet

to the end.

Now the rope is all the way through and you can fix your

cable to end of the rope and pull it gently through. Note that

this really only works well with bare ended wires – you need to add

the plugs etc. after threading.

Here

is the same X Bend Mount in a more finished state with the cable

cover plates fitted. The X motor cable runs over top and through the

small white clip.

Finally,

here is where the cables and pipes run through the benchtop:

I

bought a lot of grommets and plugs for this project and here you can

see some of them.

See you in part 4