Sunday, October 8, 2023

Monday, August 21, 2023

The Management Problem

A long time ago I saw how there seemed to be people in positions of power who really should never be in power. I called it "The Management Problem" because I think it is the biggest problem for humans ever.

This video talks about it in detail and offers suggestions for how we can solve a lot of it. It is long but very worth watching. Thankyou Brian Klaas, I wish that more people can learn from your work.

Monday, May 8, 2023

THE CNC PROJECT

Part 3

DRAG CHAINS

What are drag chains?

They are a sort of hollow chain that is used to carry the cables from the fixed part of a machine to the moving part while protecting the cables and stopping them from getting tangled up.

The OneFinity I bought did not come with any and I wanted to add a milling spindle with water cooling so I bought some and made my own mountings to fit them to the 1F.

I first looked at what other people had made on the 1F forums and one person was selling 3D printed drag chain fittings - but when I looked at them I was not happy.

There are three parts to such a set: the Top Mount, the X End Bracket and the X Bend Mount that curves all of the cables 90 degrees and then runs them into the second drag chain which goes to the benchtop.

This is his Top Mount:

I may not be a qualified engineer but I am pretty sure bending cables back 180 degrees is not a good idea.

Here is his X End Bracket and X Bend Mount:

Not bad but I think I can do a lot better. I also want to make sure that my cooling pipes from the spindle are smoothly routed as any sharp bend will restrict the flow.

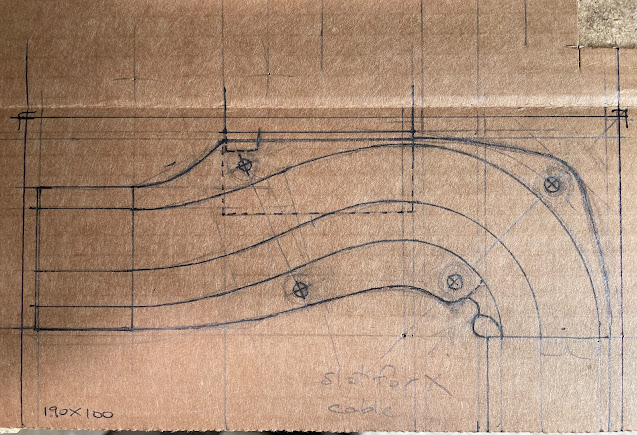

I started with cardboard and sticky tape: I stuck the bits onto the machine with masking tape and marked where things went and fiddled with things until it all worked right, then drew the shapes carefully with compass and rulers.

Here

is my pattern for the most important part, the X Bend Mount:

The idea is that the fluid pipes will go round the outside of the curve with the wires on the inside. The side walls are to be built up in two layers of 5mm thick ABS sheet while the bottom is 2mm ABS sheet.

The mountings use “L” shaped bits of the same 2mm sheet and three are used – two for the Bend mount and one for the end mount that is only there to support the aluminium rails that the drag chain rests in.

Here you can see the patterns and the parts ready to be cut from the sheet:

On the left are the side wall patterns and below them the bracket pattern.

The parts were first roughed out and then the sidewalls were glued together to final thickness before lots and lots of cutting, filing and sanding.

Note that the glue faces must be sanded first and cleaned to get a good gluing. I used “superglue” - I have some experience with it.

Note also the use of masking tape to allow drawing on black plastic sheet, an otherwise impossible task.

The mounting brackets needed two bolt holes in them so I drilled these and used the holes to bolt all three together for easier shaping.

During the production some details of the design chainged but that is normal and the main parts were checked repeatedly to make sure they would fit as planned.

This took some time but I think it all came together quite well.

Here are the finished parts: On the left, the X End Bracket, right is the X Bend Mount and below is the Top bracket.

My brackets have a step for the drag chains to mount on so that the cables run smoothly on and off the chains.

The Top bracket has a magnetic fitting under it where a clip for the dust boot pipe fixes on – you can see the magnet in the picture.

Here is how they look fitted to the machine: you can see the rails that the drag chain rests in on the X axis. Yes, I know it’s not all polished but I don’t care: it’s not worth the trouble for a piece of industrial machinery.

When the pic was taken I was getting the rails for the Y chain ready to be fitted. They are “L” profile alu extrusion screwed to the benchtop.

You can also see back end of the dust shoe I bought to run the suction back and behind the drag chain rails. More about that in part 4.

Here is another view of it, this time with the cooling pipes fitted and . .

a rope.

How do you get the cables and pipes into the drag chains?

This is my answer.

Get a rope and a driver bit. I used a phillips bit as it was less likely to catch on anything. It had a narrow collar near the back and I used a small bit of thin iron wire to fix it to the end of the rope and then covered it all with duct tape to make a smooth outside.

The last part is a good strong magnet.

I threaded the end into the drag chain and then use the magnet to pull the driver bit along inside the chain from outside. When I got to the bend I went right up to it, then moved the carriage so the bend went past the driver bit then carried on pulling it with the magnet to the end.

Now the rope is all the way through and you can fix your cable to end of the rope and pull it gently through. Note that this really only works well with bare ended wires – you need to add the plugs etc. after threading.

Here is the same X Bend Mount in a more finished state with the cable cover plates fitted. The X motor cable runs over top and through the small white clip.

Finally, here is where the cables and pipes run through the benchtop:

I bought a lot of grommets and plugs for this project and here you can see some of them.

See you in part 4

THE CNC PROJECT

Part 2

DUST AND MORE DUST

All milling machines make dust – or swarf, or shavings or whatever you want to call it, but the faster they work and the better they cut, the more dust they make and you better have a way to clear that away for your milling head or it will clog up, overheat and maybe even break a tip.

So you need a dust collection system.

Yes, you could just get a shopvac but that won’t cut it: once the vac bag gets about half full its suction drops off and you are forever going to be buying new dust bags, and this thing is going to be sucking a lot of dust over long periods.

What works so much better is a cyclone filter. This is a specially shaped chamber that causes a “cyclone” in the air that gets the particles in the air to drop out. This goes in front of the vac so that the air being sucked into the vac is almost clean while all of the dust is easily collected out the bottom of the cyclone.

At first I thought of putting the whole thing under the CNC but this is a very useful thing to have: almost every workshop power tool makes dust and they have a collection port that you can hook up the vac to, so why not have it on a mobile trolley for general use?

The cyclone cost $32. The Shop Vac was $100. Other than that there were some bits of 50mm PVC plumbing and a metal 20L drum I found for free at my work. I had a trolley that I got for some other use that just happened to be exactly big enough to fit the shop vac on the bottom shelf. I estimate the total cost at $180.

Just have a look at how much the fancy shop vacs go for and note that these do not usually have cyclones on them: you will be buying a lot of dust bags if you want to use them for a CNC mill.

The big pipe has a threaded joiner in the middle that acts as a swivel so that the top can be removed from the cyclone (the black bit) and the drum has a clamp on it that can be undone to get the dust emptied. The fitting on the bottom that locks onto the vac has a swivel that is airtight and has slots that lock on the pins on the vac body so you can remove the bits above it easily to empty the vac itself (although this won’t be often).

There are other neat details but the main thing is that it all works well. See the picture below.

As a project this worked out really well. It made me think and it was good practice putting various parts together to make something that works properly.

It also kept me going while I waited for parts of the CNC to arrive. There was a lot of waiting involved.

Sunday, May 7, 2023

THE CNC PROJECT

Part 1

Overview

What I really want is to make nice clean things that work because the parts all fit together neatly. I want to make some spinning motors and such in future and that needs high quality accurate machining. It will take time to develop, yes, but the results will be usable as opposed to rough-as-guts hand manufacture. I know that only too well.

The best way to do this is with a CNC Mill. That’s Computer Numerical Control. When I worked in a machine shop as a teenager the CNCs were big and expensive. We cut stainless steel like it was cheese.

Nowadays there are small, cheap and low power models that you can run from your garage. This is defined as subtractive machining – you take a lump of material and subtract the bits you don’t want from it. The opposite is additive machining, or 3D printing. I have one of those too – they are good but the parts it makes cannot equal the strength of a machined aluminium part. Having both in your workshop is the best option.

I looked around the net and after careful thought I decided on the OneFinity Woodworker X-50 32 x 32 inch. It cost about $5K AUD including delivery from Canada.

Why did I choose the OneFinity?

1. Ball screws. It has Ball screws which are solid unlike a lot of other machines which have belts. Belts are fine for machinery that does not take a lot of force such as 3D printers, but for milling they are just too weak imo.

2. Solid construction with linear bearings. This is the only home CNC that has decent rails and lead screws.

3. Flexibility with the choice of machine head and software.

The maker does not recommend using it for cutting steel and that is fine. They also don’t supply a milling head or drag chains and that’s fine, I will get my own. They supply the three motion axes, the controller box for them and the control panel. There are a few extras that are worth getting from OneFinity such as the touch probe but everything else you get for yourself and assemble yourself.

So now there is a whole lot of work to get all of the parts together and assemble them into a working machine - metalwork, woodwork, electronics, plastic work, painting, design . . . . there’s all of them needed and a few other things too. Then once it is all working I need to work out the software to make it all go.

I

actually started the whole thing in august last year. There has been

a lot of time spent waiting for parts to arrive and a lot of

frustrations when things did not go according to plan, but now it's looking pretty good.

The Bench

The machine needs a solid bench and I bought one, twice.

The frame of the bench needs to be solid and it looks like the best one is made by a company called Kreg. It comes in parts that bolt together and it is thick steel – but for some reason they are very hard to get here in Oz. The first time I ordered it they refunded me a week or two later because they could not get one.

I ended up having to buy a smaller one just for the vertical legs and a set of long horizontal bars direct from the US. It was worth it though, I did not see any other item that was as solid.

I tried out other options - (getting cheap chinese metal benches and widening them) - but they were so flimsy and wonky that the bench would never have been stiff enough to use. They are okay for what they are – I have three in the garage, but no good for mounting the CNC on.

Then there was the bench top.

I could not get plywood thick or wide enough for my initial plans so I ended up getting thinner 12mm sheets, redesigning things so the bench was only 1220 deep (max plywood width) and then gluing two sheets of the ply together to make one solid plate 24mm thick to mount the CNC on.

I don’t recommend this to anyone: with no proper tools or even a bench 1220 x 1300 to sit them on it while gluing it’s surprising that they turned out okay. Even then the whole thing is not quite flat: it has a slight bulge in the centre.

I had hoped that gluing them together would flatten it but nope.

Now that the machine is bolted to it I will use the machine itself to mill the middle of the bench flat before I put the spoil board on.

Other bits

I added a lower level shelf from some bits of a cheap metal bench and another piece of the same plywood to stabilise the bench a bit and give me somewhere to put other parts of the machinery out of the way – the electronics, the water cooling system for the milling head and the suction hoses and so on.

------------------------------------------------------

The plan

I didn’t just throw all of this together, I made plans from the start – and I designed, re-designed and re-re-designed things in 3D using Blender, my preferred design tool.

This

is version twentyfour of the Blender model, and for reference below

is a photo of the real thing : Not

too far off. The cover frame is only a test fit here.

I am missing out a lot of the details here, trying to give a short report on a very long and drawn out project. This is where I spend my weekends.

More

soon in Part Two. Thanks for reading.

Monday, May 23, 2022

Bike Cables and Rusty Bits

I have already replaced a lot of bolts on the bike with stainless steel ones : it seems that wherever you put a hex driver or wrench, the paint comes off and it starts to rust after a shower or two, and there has been a lot of rain around here lately.

Ferrules are those little bits at the ends of the cable tubes. Those on my E-bike were chromed metal and they were rusting within a week of rain hitting them.

“No problem” I thought, and bought a set of replacement corrosion proof ferrules, cables and the tool to cut the tubing.

A little detail on the nature of bike cables: the brake cables and shifter cables are not the same. Yes, they look the same but they are not. The brake cables are thicker and have 5 mm tubes. These tubes have a spiral wound metal tube with plastic covering outside and slick plastic liner inside. The shifter cables run in 4 mm tubes and the metal tube is more like a hollow cable itself: the strands run along the tube which makes a stiffer tube, more resistant to tension. You should not mix them up. The top ends of them have fittings specific to their function and this should help you figure out what they are if you don’t know.

|

| Left - Brake cable, Right - Shifter cable |

I started out replacing the tubes on the brake cables. The tube cutter worked fine, Then I filed the cut ends to get them neat and used the pointed bit on the tool to make sure the hole in the middle was clear to run the cable through. In a short time the replacements were done. I did not fix the new alloy ferrules to the cable tubes but it does not matter as they aren’t going anywhere. I also lubed the cables with dry lube.

|

| Cable tube tool |

The shifter cable was a whole different thing. First, the shifter cable has three tubes on it. I didn’t know about the difference between tubes at that point and went to chop it with the same tool I used for the brake cables – it just made a mess. It distorted the tube and didn’t cut all of the strands. Fortunately I have a "grinder" tool and so I used that to cut the end of the tube off neatly. It took me a couple of tries to work this out as the heat from cutting melted the plastic on my first try – if you want to cut the tubing this way, chop a little at a time and wait for it to cool off before cutting more. This gives a very neat end provided that you are patient. Then you only need something like a piece of wire or a bent paperclip to clear the end of the hole and it is ready to use.

|

| The "grinder" tool with saw blade |

This would have made fitting the cable tubes easy and fine except that . . . The cable itself decided to lose a fibre. This rucked up when I put a tube on and made using the tubes impossible. Once it is bent you can’t really unbend it. A frayed thread or fibre can be rewound back into the cable if it is still curled as it was before but a sharp bend in one is another story. All I could do was cut it off high enough that the cut tip did not scrape on the tubes and wind it carefully back into the bundle.

I now have a new shifter cable and will try to fit this soon. Fortunately, the end of the new cable is already fused together. Fine until you have fitted it and then you will probably want to trim off the end so it doesn't hang down – and there, your fused end is gone. Also, once you undo the cable from its clamp at the end it is squashed and this can make it hard to pull the tubes off or get new ones on. Oh, yes – there is more than one end design, depending on the maker of the equipment.

I would have already put a new cable on except that I don't know how to get the top end out of the controller.

I have opened the side of the shifter controller but I can’t see either the end of the cable or where to remove it.

I went to the maker's website and got the service info for the specific model and . . . . it says nothing about how to replace the cable. Nothing. Cable part number, picture of it, yes - how to do it, no. The trouble with flying blind is that if anything goes wrong, for example a spring flying out of the unit as I take it apart (never to be recovered) – the bike is then unridable. My only answer: buy a new item of the same model and wait until it arrives, then take it apart to figure out the process. Once I have that, I can be sure that I can get it back together or replace any broken or missing bits.

There are a lot of webpages and vids of "How to change the bike cables" but none of them showed the same model as I have or dealt with any of the problems I had, which is why I am posting this here. They all make it sound so quick and easy - but it isn't.

That's it for now. I hope any cyclists out there can gain something from my experiences trying to do my own repairs. I could have taken the bike to a shop and paid plenty to have someone else do it - but there is a problem: I don't own a car so how do I get it there? - and really, I want to do it all myself.

Friday, April 1, 2022

Carrier Project Update

After some use I learned that the main rails were flexing under load and I wanted a proper carry box as well – one that was watertight and strong . The case I found is one of those sold for camera equipment and has a very good seal around it. It also has holes in it where you can put a padlock.

I then added some aluminium rail brackets underneath so that it slides onto the rails on the carrier.

The carrier needed to be remade to fit the case and when I did I added some reinforcing bars to stiffen it too. I also added a lock so that the case can be locked onto the bike.

I am now very happy with it, and the bike in general. I ride it to work every day and take it on long rides when the weather is good on weekends.

The last thing I have to do now is to make the bike rust proofed. Some of the nuts and bolts have surface rust on them due to a lot of rain lately so I am replacing them with stainless steel bolts where possible and I have some special paint to deal with other parts.